Name:202A Egg washer

Product Code:202A

Capacity:10,000 eggs/hour

Function:sanitizer sprayer, washing, drying ,optional accumulator & candling, vacuum egg lifter,printer

Details

Overview

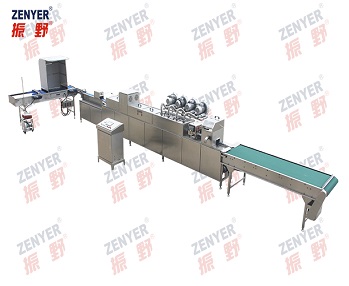

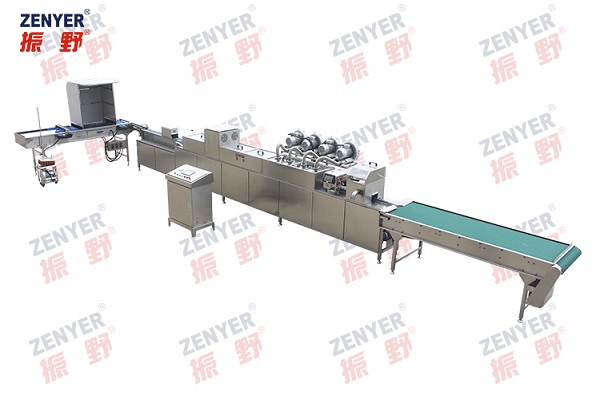

The ZENYER 202A egg washer combines advanced modular design with professional-grade performance, delivering complete sanitizing, washing, and high-efficiency drying for medium to large-scale operations. Integrating the 605AS accumulator, 202A main unit, and optional accessories, this robust stainless steel system handles up to 10,000 eggs per hour. It ensures thorough cleaning with soft brushes and warm water, followed by an effective drying process that achieves 95–99% dryness—making it ideal for standalone use or as part of a fully automated washing and grading line.

Features:

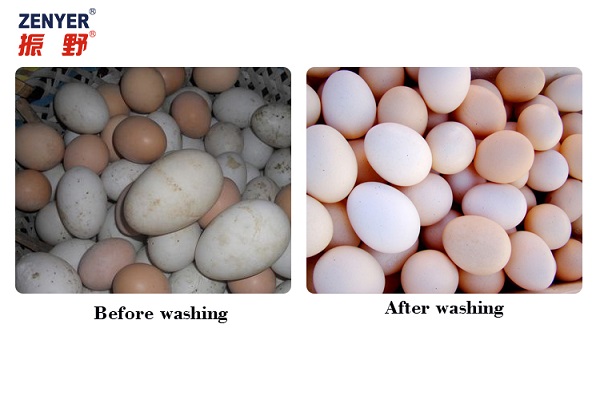

Complete washing & Drying Process

Eggs are automatically sanitized, washed with soft brushes and warm water, and dried using a combined brush-and-fan system that removes up to 99% of moisture.

Modular & Scalable Design

Includes the 605AS accumulator and 202A washer main unit, with options such as the 602 vacuum egg lifter and 401H egg printer for a customized workflow.

Integrated Quality Control

Features six-row LED candling strips beneath the accumulator, along with a candling cover and mirror, for easy detection and removal of defective eggs.

High-Capacity Operation

Processes 10,000 eggs per hour with smooth vacuum lifting and single-line feeding into the washer, reducing manual labor and ensuring consistent throughput.

Hygienic & Durable Construction

Built entirely from strong stainless steel for long-lasting, food-safe performance and easy cleaning and maintenance.

Ready for Full Automation

Easily connects with ZENYER 104A or 104B egg graders to form a integrated 10,000 eggs/hour washing and grading line (ZENYER 302A/302AS).

| Commodity | Egg washer |

| Product code | 202A |

| Model | ZYX-JS1-3-(P) |

| Capacity | 10,000 eggs/hour |

| Material | Stainless steel |

| Power | 10.9KW |

| Voltage | 380-415V, 50HZ, 3-phase |

| Dimension (L*W*H) | 9.4*3.9*2.0 M |

| Net weight | 1015KG |

| Gross weight | 1470KG |

| Function |

Accumulator & candling,sanitizing,washing, drying, optional vacuum egg lifter,egg printer and manual collection conveyor |

.jpg)

For ZENYER 202A egg washer without manual collection conveyor : Only CNY194,500.00

Option:

The 602 Vacuum egg lifter : CNY8,750.00

The 401H egg printer : CNY26,000.00

The 608B manual collection conveyor (UV included) : CNY23,350.00