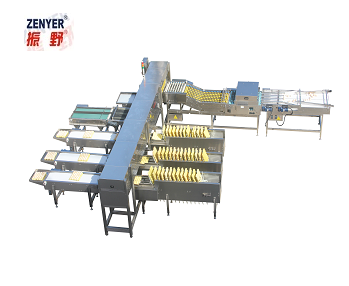

Name:FBC20-3 Egg grader (107)

Product Code:107

Capacity:20,000 eggs/hour

Function:Candling, head turning, grading & counting, auto-packer

Details

ZENYER 107 High-Capacity Egg Grader

Precision, Efficiency, and Automation for Modern Egg grading

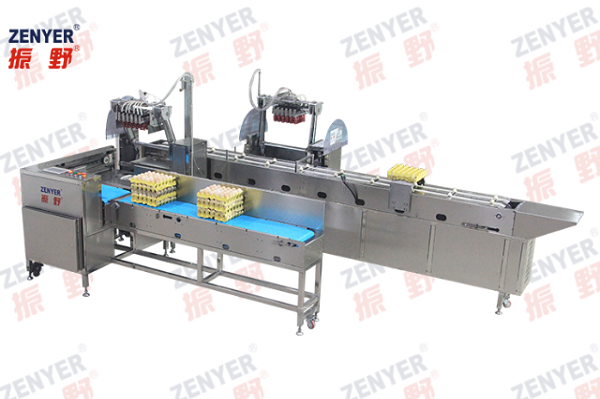

Engineered to excel in high-demand environments, the ZENYER 107 Egg Grader combines robust construction, intelligent control, and seamless automation to deliver unmatched grading accuracy and operational efficiency. With a remarkable capacity of 20,000 eggs per hour, it is designed to meet the needs of large-scale commercial egg producers.

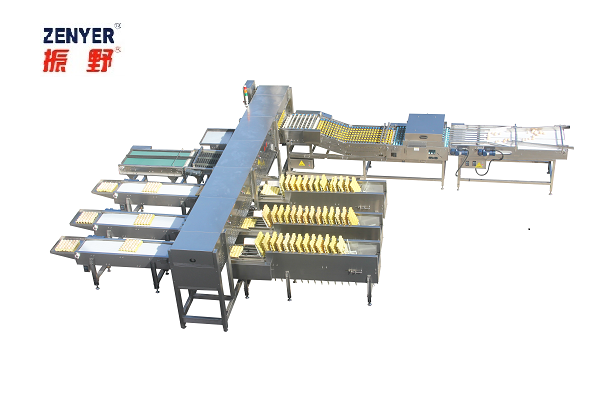

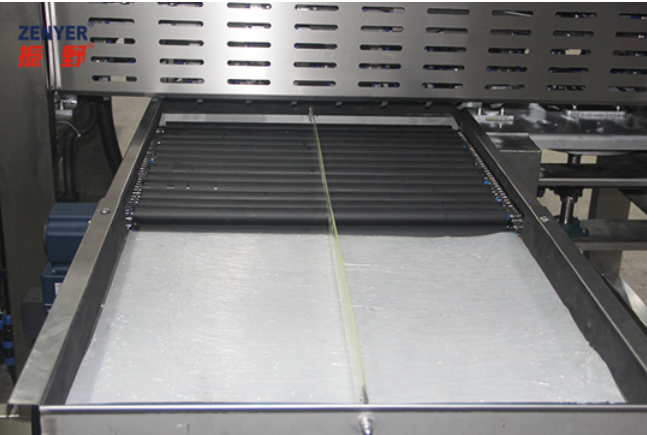

Durable & Hygienic Stainless Steel Build

Constructed from high-quality stainless steel for long-lasting performance and easy cleaning, ensuring compliance with strict hygiene standards in demanding processing environments.

All-in-One Integrated Processing

Perform accumulating, candling, orientation, grading, counting, and auto-packing in one streamlined system. Eliminate the need for multiple machines and reduce handling while maximizing throughput.

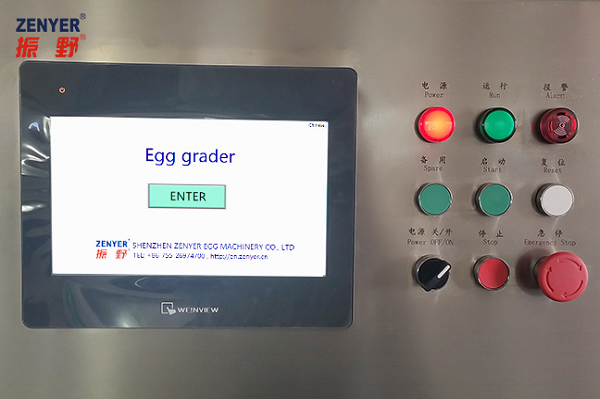

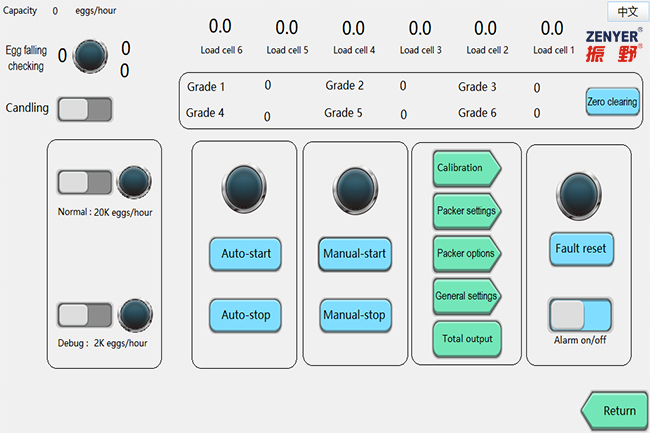

Smart Touchscreen & PLC Control

Simplify operation and monitoring through an intuitive color touchscreen and reliable PLC control system. The built-in self-diagnosis function helps quickly identify issues, minimizing downtime.

Flexible Egg Loading

Connect directly to a rod conveyor from the chicken shed for continuous automated intake, or use the ZENYER 615 Automatic Egg Loader for rapid and efficient loading onto the roller conveyor.

Advanced Candling with LED Inspection

Equipped with an LED-lit candling booth, cover, and mirror to enhance visibility. Operators can easily identify and remove cracked, dirty, or defective eggs, ensuring only high-quality products are packed.

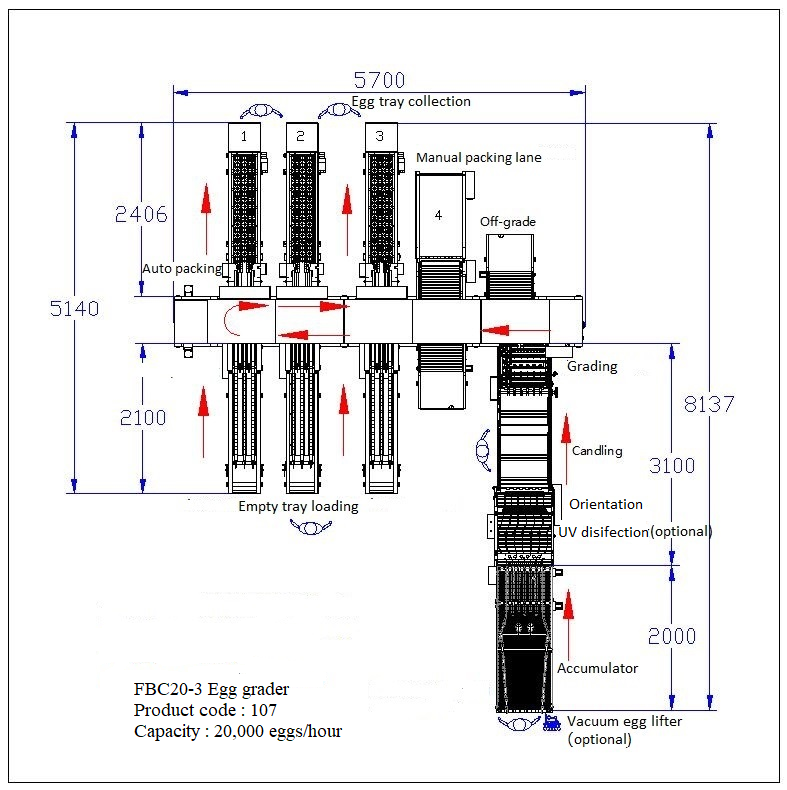

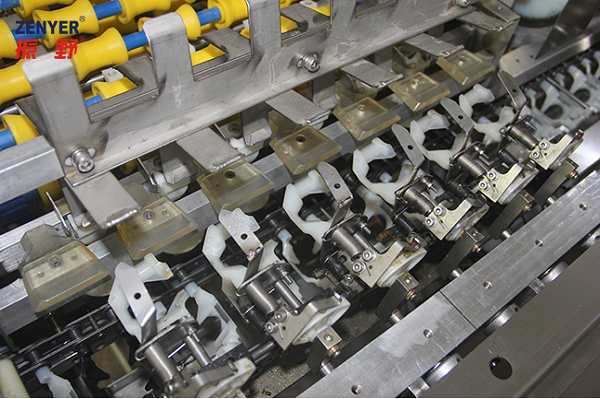

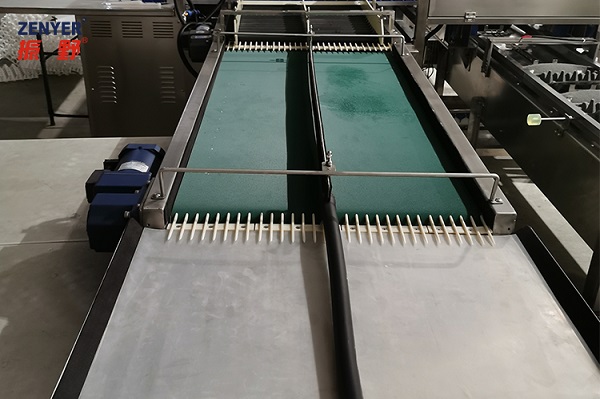

Automatic Egg Orientation

Positions eggs with the air chamber facing upward to preserve freshness and extend shelf life, ideal for prolonged storage and distribution.

Optional UV Disinfection

Add an extra layer of food safety with optional UV disinfection, effectively sanitizing eggshells to meet elevated hygiene requirements.

Precision Grading & Real-Time Counting

Accurately sort eggs into 4–7 weight grades with ±1 gram precision. Monitor total output and per-grade counts in real time for better production planning and quality control.

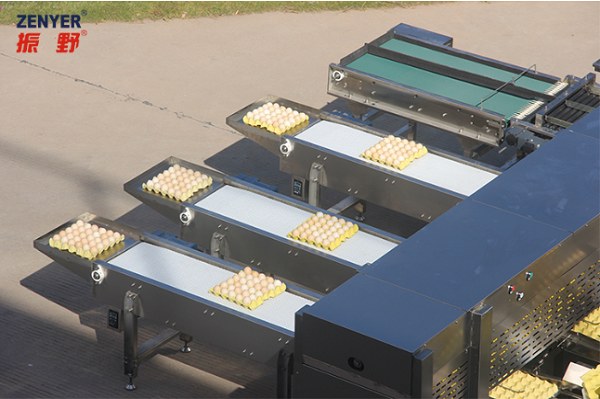

Versatile Auto-Packing Configuration

Includes 3 auto-packers and 1 manual packing lane, with the option to convert the manual lane into an additional auto-packer. Supports a wide range of carton sizes (10, 12, 15, 18, 30 eggs), and routes off-grade eggs to the manual lane for handling. The manual lane can also be split to pack two sizes simultaneously.

Scalable System Integration

Easily combine with the ZENYER 203A Egg Washer to form a complete ZENYER 303A Egg Washing & Grading Line, maintaining a high capacity of 20,000 eggs per hour for end-to-end processing solutions.

| Commodity | Egg grader |

| Product code | 107 |

| Model | FBC20-3 |

| Capacity | 20,000 eggs/hour |

| Material | Stainless steel |

| Accuracy | ±1g |

| Grade | 4-7 |

| Power * | 5.95KW |

| Voltage | 380-415V,50HZ,3-phase |

| Dimension (L*W*H) | 7.6*5.7*2.0 M |

| Net weight * | 3010KG |

| Gross weight * | 4550KG |

| Function | Accumulator,Candling booth & head turning,grading & counting,auto-packer, manual packing lane,off grade table |

Accumulator (candling,head turning included)

The 107 main machine

Manual packing lane (1 unit)

FBC20-3 Egg grader (107) Brochure